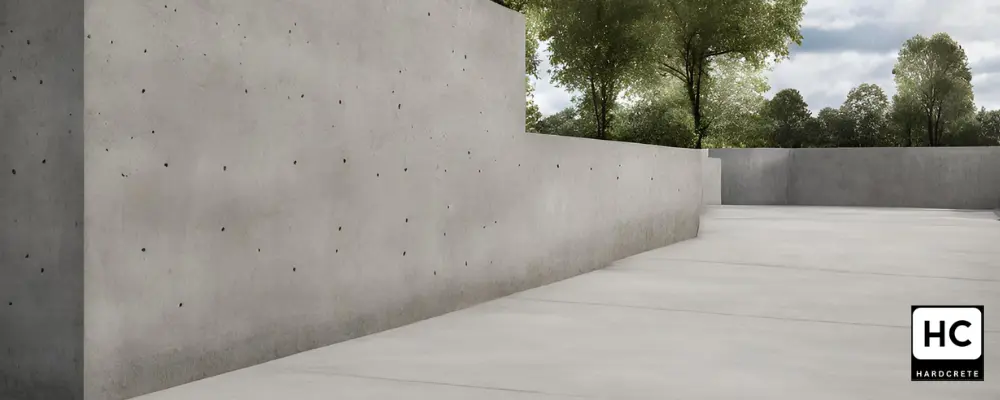

Exploring the Concept of Sustainable Concrete

The concept of sustainable concrete involves utilizing green concrete, which focuses on the sustainability of concrete production processes. Green concrete integrates environmentally friendly materials, like agricultural waste, to reduce the carbon footprint associated with traditional cement production. It emphasizes the life cycle and sustainability of concrete as a building material, contributing to the reduction of CO2 emissions from cement plants and power plants. The goal is to maintain or enhance the compressive strength of concrete while minimizing the impact on the environment, making it an essential consideration in modern civil engineering and construction companies.

Traditional Concrete vs Sustainable Concrete: An Overview

In comparison to traditional concrete, sustainable concrete significantly reduces carbon dioxide emissions and encourages the conservation of natural resources. Unlike traditional concrete production methods that often overlook initial costs, sustainable concrete presents cost savings and lower energy consumption. Additionally, it effectively mitigates the urban heat island effect in urban areas, making it an environmentally friendly building material with substantial benefits for the construction industry.

Environmental Impacts of Traditional Concrete

Conventional cement production contributes to environmental degradation by causing water and land pollution. It generates large amounts of waste, including demolition materials, and emits substantial tons of carbon dioxide, impacting air quality. The lack of awareness regarding initial costs also affects infrastructure projects. Utilizing green concrete and environmentally friendly building materials can address these concerns in the concrete industry, promoting the sustainability of concrete in civil engineering and construction companies.

The Key Components of Sustainable Concrete

Understanding the composition of green concrete is paramount. With cement production being a major contributor to carbon emissions, sustainable alternatives are imperative for the concrete industry. Supplementary cementitious materials, such as silica fume, and recycled aggregates play a vital role in reducing the environmental impact of traditional cement manufacturing. Admixtures further enhance the sustainability of concrete, improving its strength and durability while reducing the cement content. Embracing these key components is essential for the long-term sustainability of concrete in civil engineering and construction companies.

Understanding Supplementary Cementitious Materials

Supplementary cementitious materials play a crucial role in reducing carbon dioxide emissions and promoting energy savings and waste reduction strategies. Their applications not only offer cost savings and reduced environmental impact but also focus on the conservation of natural resources and sustainable concrete production. These materials contribute significantly to the resource efficiency and overall sustainability of concrete, making them an essential component in the construction industry’s move towards environmentally friendly practices.

The Role of Recycled Aggregates

In sustainable concrete production, the use of recycled aggregates significantly reduces carbon dioxide emissions, promoting resource efficiency and conservation of natural resources. These aggregates play a crucial role in waste reduction strategies, leading to cost savings and minimizing environmental impact. Their applications enhance sustainable concrete production techniques, contributing to the sustainability of concrete as a building material. This approach aligns with the focus on environmentally friendly concrete and the life cycle of green concrete, emphasizing the importance of utilizing recycled materials in cement production.

Importance of Admixtures in Sustainable Concrete

Admixtures in sustainable concrete significantly contribute to energy savings and waste reduction strategies, promoting both cost savings and environmentally friendly production. They play a vital role in reducing carbon dioxide emissions and enhancing the durability of concrete. With a focus on conserving natural resources and ensuring resource efficiency, these admixtures are essential for the overall sustainability of concrete in the construction industry. Their incorporation in the cement production process is crucial for achieving the desired compressive strength and life cycle performance of green concrete.

The Production Process of Sustainable Concrete

The production process of sustainable concrete involves the careful selection and use of materials to minimize environmental impact. By reducing the cement content and incorporating supplementary cementitious materials like silica fume, agricultural waste, or recycled materials, the cement industry can greatly enhance the sustainability of concrete. Additionally, efficient manufacturing techniques and the utilization of power plants’ by-products further contribute to the green concrete’s life cycle and its environmentally friendly construction applications in civil engineering and green building projects.

Strategies for Reducing CO2 Emissions

To enhance the sustainability of concrete production, strategies focus on reducing carbon dioxide emissions and environmental impact. This involves advanced production methods and efficient material extraction to minimize energy consumption and waste. The emphasis is on conserving natural resources and designing sustainable concrete that promotes efficient use of resources. These strategies are pivotal in cement production and construction, aiming to minimize the carbon footprint and overall environmental impact of the concrete industry.

Efficient Use of Resources in Production

Efficient resource utilization emphasizes cost-effective measures and waste reduction, aiming to minimize environmental impact and energy consumption. It advocates for the conservation of natural resources through advanced production methods, sustainable concrete design, and efficient material extraction. These strategies play a crucial role in reducing carbon dioxide emissions and enhancing overall sustainability, aligning closely with the green initiatives within the construction industry.

Minimizing Waste: A Step Towards Sustainability

Minimizing waste in sustainable concrete production is crucial for reducing environmental impact and conserving natural resources. By implementing waste reduction strategies and utilizing waste materials in cement manufacturing, the industry can achieve resource efficiency and promote sustainability. Advanced production methods not only lead to cost savings but also contribute to environmentally friendly concrete. These applications play a significant role in sustainable construction practices, emphasizing the importance of minimizing waste as a fundamental step towards sustainability.

The Multifaceted Benefits of Sustainable Concrete

Environmental benefits are a key aspect of green concrete, contributing to the sustainability of the construction industry. The compressive strength and durability of environmentally friendly concrete make it a reliable and cost-effective building material for construction companies. Additionally, reducing tons of carbon in cement production and promoting the life cycle of sustainable concrete are crucial for the sustainability of concrete industry. Embracing the use of silica fume and agricultural waste in cement manufacturing further enhances the sustainability of concrete.

Environmental Benefits: A Closer Look

The environmental benefits of sustainable concrete are significant. Production methods reduce water pollution and waste generation, promoting environmental sustainability. Utilization of waste materials minimizes the carbon footprint of construction projects, lessening climate change impact. Sustainable mix design reduces carbon dioxide emissions. Additionally, construction with sustainable concrete conserves natural resources and raw material extraction, making it an environmentally friendly building material. The cement industry is increasingly embracing the sustainability of concrete, contributing to greener practices in civil engineering.

Economic Advantages of Sustainable Concrete

Advanced sustainable concrete production techniques result in cost savings and resource efficiency, offering a friendly alternative with sustainable resource consumption. By utilizing waste materials in concrete manufacturing, initial costs are reduced, contributing to the conservation of natural resources and overall cost savings. Moreover, the application of sustainable concrete in infrastructure projects leads to reduced costs due to advanced production methods. This not only promotes economic advantages but also aligns with the sustainability of concrete within the construction industry.

Social Impact and Responsibility

Promoting awareness and responsibility towards sustainability, sustainable concrete production methods play a pivotal role in acknowledging social and environmental responsibilities. Addressing the lack of awareness and land degradation, sustainable concrete properties and production methods contribute to the betterment of urban areas and sustainable infrastructure projects. By supporting sustainable construction, the utilization of sustainable concrete materials actively contributes to the conservation of natural resources, highlighting the social impact and responsibility it carries within the construction industry.

Practical Applications of Sustainable Concrete

Sustainable concrete, also known as green concrete, is gaining traction in the construction industry for its environmentally friendly properties. It is being widely used by construction companies in green building projects and infrastructure development due to its sustainability. The compressive strength of sustainable concrete makes it an ideal building material, reducing the carbon footprint in the production process. This innovative approach to construction aligns with the long-term sustainability goals of the cement industry and civil engineering. Its use in various applications showcases the growing trend toward environmentally friendly concrete.

Promoting sustainable construction practices, the utilization of environmentally friendly concrete materials supports green building projects. With properties and production methods designed to lessen water pollution and waste generation, sustainable concrete contributes to sustainable urban areas and resource conservation. Additionally, its applications play a crucial role in minimizing carbon dioxide emissions and reducing environmental impact. By incorporating sustainable concrete, construction companies and civil engineering projects can significantly enhance the sustainability of their initiatives.

Future Prospects and Challenges in Sustainable Concrete Utilization

Overcoming Initial Cost Hurdles:

As sustainability becomes a focal point in construction projects, initial cost hurdles pose a challenge. Implementing sustainable concrete may initially require higher investments compared to traditional materials, but the long-term benefits outweigh the initial costs. Educating stakeholders about these benefits and offering incentives for sustainable practices can help overcome this challenge.

How is Sustainable Concrete Contributing to a Greener Future?

Sustainable concrete plays a pivotal role in reducing the carbon footprint of the construction industry. By incorporating eco-friendly materials, optimizing production processes, and reducing waste, sustainable concrete aligns with the industry’s commitment to environmental responsibility. Overcoming challenges such as initial cost perceptions will further drive the integration of sustainable concrete, leading to a greener and more sustainable future.

Frequently Asked Questions

What is the most sustainable type of concrete?

The most sustainable type of concrete incorporates recycled materials like fly ash or slag, reducing the environmental impact. Locally-sourced materials also decrease transportation emissions. Alternative options such as hempcrete, timbercrete, and ferrock offer sustainable alternatives to traditional concrete. Additionally, integrating green roofs and walls into building designs enhances sustainability.

What is eco-friendly concrete?

Eco-friendly concrete is a sustainable alternative to traditional concrete, with reduced environmental impact. It can be made using recycled materials like fly ash or slag, or alternative binders such as geopolymer or hempcrete. By using eco-friendly concrete, we can lower carbon emissions and conserve natural resources.

How is Sustainable Concrete Made?

Sustainable concrete is created by incorporating alternative materials like fly ash or ground granulated blast furnace slag into traditional cement mixtures, reducing the need for cement. It can also be made by using recycled aggregate instead of traditional aggregates, helping to minimize carbon emissions and waste in the construction industry.

Conclusion

In conclusion, sustainable concrete offers a promising solution to reducing the environmental impact of traditional concrete production. By incorporating supplementary cementitious materials, utilizing recycled aggregates, and employing admixtures, we can create a more sustainable and eco-friendly building material. The production process can be further optimized to reduce CO2 emissions, efficiently use resources, and minimize waste. The benefits of sustainable concrete extend beyond the environment, with economic advantages and social responsibility. Its practical applications in green building projects and infrastructure development are gaining momentum. However, challenges such as initial cost hurdles need to be addressed. As we move towards a greener future, sustainable concrete plays a crucial role in building a more sustainable and resilient world.